Simulation Modeling

What is Simulation Modelling?

Simulation Modeling is one of the ways to solve complex problems that appear in the real world. Sometimes we cannot find the right solution by playing with real objects like buildings, people, equipment, etc., because either they are very expensive, dangerous, or just not feasible.

Using modern computing technology you can build a model of the real world with user controlled level of detail or abstraction. You can then run a simulation (2D or 3D) for various real-world scenarios to narrow down the solution. Simulation software allows you to test various what-if scenarios without breaking ground.

There are various modeling approaches: System Dynamics, Discrete Event, and Agent-based. Hence, there are various tools that support these different approaches. Some require a fair degree of knowledge of statistics or programming. Other tools may require knowledge of the industry, e.g. transportation or supply chain. 4Sight | OT | SET has partnered with some of the leading modeling and simulation software development companies to offer you access to the best-in-class modeling and simulation software.

Simulation Modelling Benefits

Simulation Modeling Process

Below are the steps we follow in order to optimise your process using simulation modeling.

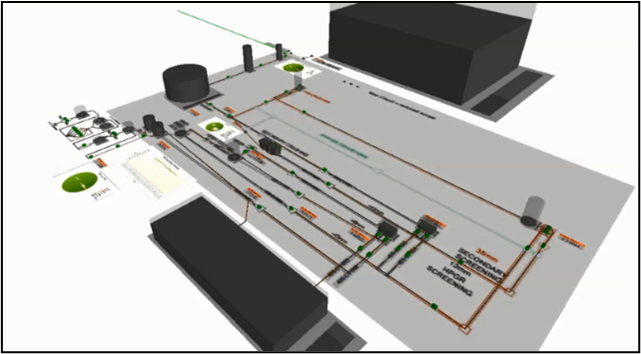

1. Integrated 3D technology provides an immersive visual experience.

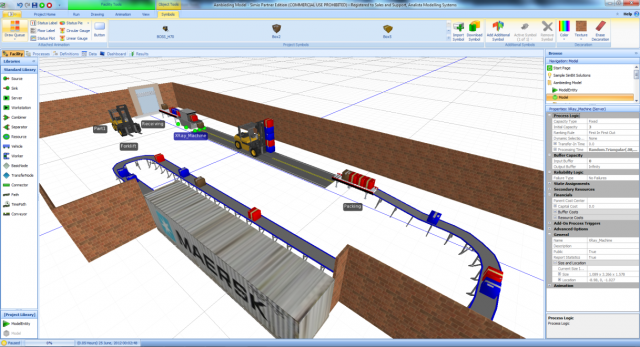

Simio is designed from the ground up using advanced 3D technology that is included at no extra charge. Beware of products that have older 2D technology – with 3D post-processors added as an afterthought and sold as an expensive add-on

Concurrent 3D allows you to see immediate results of model changes and instantly switch between 2D and 3D views

Simio is the first product to integrate Google 3D Warehouse for free access to over a million 3D symbols

Visual Validation

The first level of model validation, where you visually confirm that the system is working—or not working—as it was intended to.

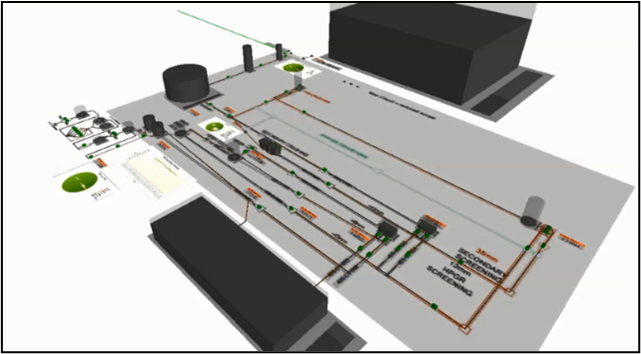

- Model a real system in our native 3D virtual environment

Account for real-world variability with FlexSim’s vast array of statistical distributions and random numbers

Run simulation using the model to test “what if” scenarios—without needing to change things in the real world

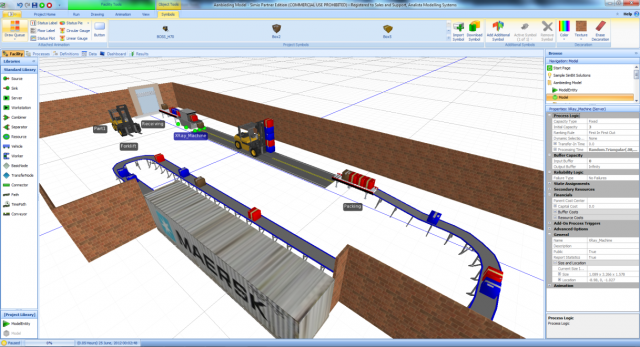

2. Model Layout

Simio makes it as easy as possible to replicate the look of your system while preserving the details necessary for accurate analysis.

Just use the simple drag-and-drop controls to place objects and resources directly into the 3D environment—no post-processing needed!

Our 3-axis layout and CAD drawing import help you maintain the exact spatial relationships in the actual system, so travel and transport times will be accurate.

Import custom 3D objects to replicate the look and feel of the actual system. Plus all realistic visual effects, like shadows and lighting effects, are ready to go by default.

3. Model Building

Simio toes the line between ease-of-use and capability to model even the most complex systems.

The Standard Object Library contains a variety of objects that be used to immediately build models. Customization is simple—just choose from the preconfigured behaviors, mix-and-match options, and even create your own behaviors.

Production Scheduling integration to easily combine with any MES software.

Our advanced Process Flow Library allows for easy integration with mining and other industrial applications which rely on flow rates.

4. Model Analysis

Once you’re ready to simulation using your model, our full suite of analysis features will help you get a deeper understanding of what’s going on.

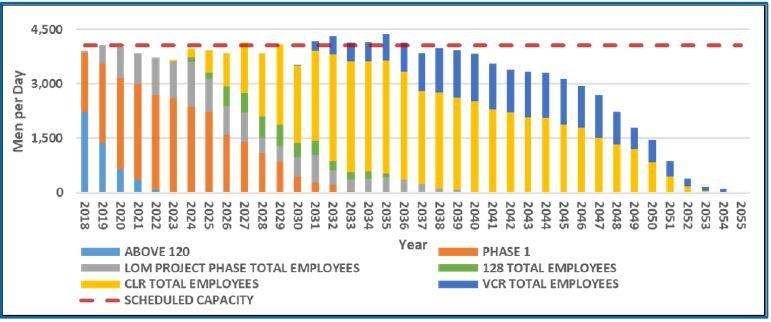

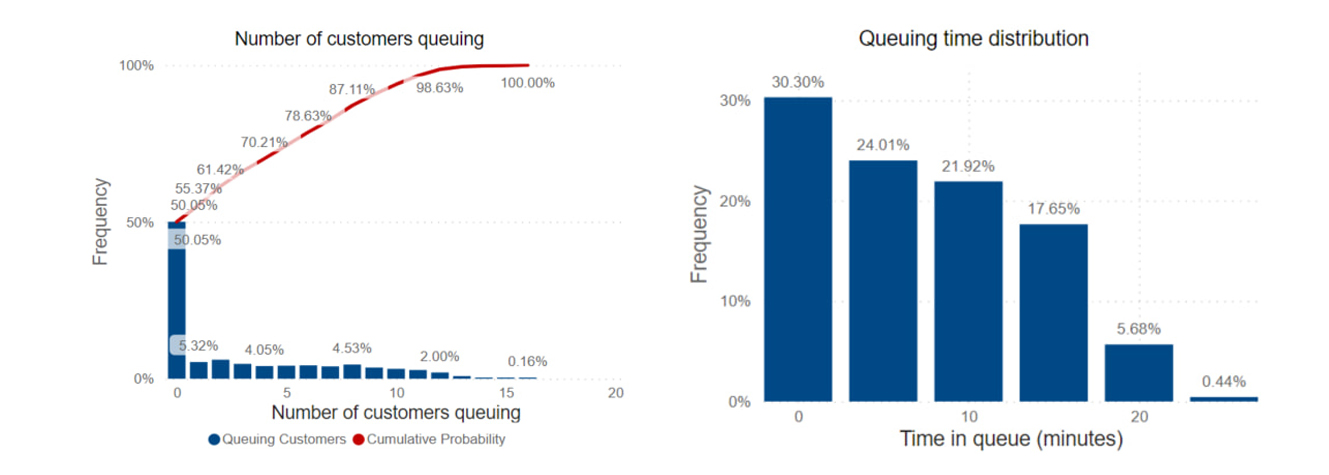

- A deep roster of charts and graphs to help you visualize data from a simulation run

The ability to track a wide range of data points and then export to your favorite spreadsheet application

Greater flexibility for data gathering through powerful tools like the Stats Collector object and Zone activity

Statistical Validation

The second level of model validation, where you evaluate data from one or many simulation runs to verify that the system is operating as expected.

5. Optimise your process

Where the money is made (or saved)! Test “what if” scenarios to find the best possible choices to make in the real world.

Simio + OptQuest

If you want to add optimization to your toolkit, Simio is fully integrated with the OptQuest engine. This powerful scenario optimization package lets you set variables and constraints on your model to evaluate hundreds of possible solutions. You can even design experiments with multiple objectives to consider competing forces in the system. Find the best possible solution for your process with Simio and OptQuest.

Test Multiple Scenarios

Use our powerful Experimenter tool to test multiple scenarios and compare the results. Replications are spread over your CPU cores, so hundreds of simulated replications across many different scenarios can be completed in minutes—not hours or days. The Experimenter also includes report generation and control over variables and performance measures.

Simulation Training

SET’s experienced team offers training for getting started with simulation modeling and developing advanced skills. We bring real-world lessons learned from our consulting engagements to help you build knowledge from the ground up. We share best practices, identify pitfalls and help clients fast-track solutions for their areas of focus.

Ready to enhance your organisation?

Fill in the form below and one of our engineers will contact you shortly